Birkenhead, South Australia

New build using reverse brick veneer and structural insulated panels

Photo: Mark Clayton, Sustainability House

NatHERS Thermal comfort rating

7.9 stars

Heating: 21.4MJ/m2/year

Cooling: 23.4MJ/m2/year

Total: 44.8MJ/m2/year

Sustainability features

- Passive design

- Sealed building fabric

- Reverse brick veneer

- Thermal mass

- Structural insulated panels (SIPs)

- Double glazed windows

- Ceiling fans (no other mechanical heating or cooling)

- Light emitting diode (LED) lighting

- Heat pump hot water system

- Solar photovoltaic (PV) system

- Insulation, R3.2 insulation in all walls and R6 bulk insulation in the ceiling

- Monitoring systems track internal temperature, humidity, energy consumption and solar PV production

- Zero volatile organic compound (VOC) paint and floor treatments

- Rainwater tanks with a total capacity of 7,000L

Project details

Building type: low density

NCC Climate zone: 5 – warm temperate

Designer: SUHOstudio

Builder: Owner builder

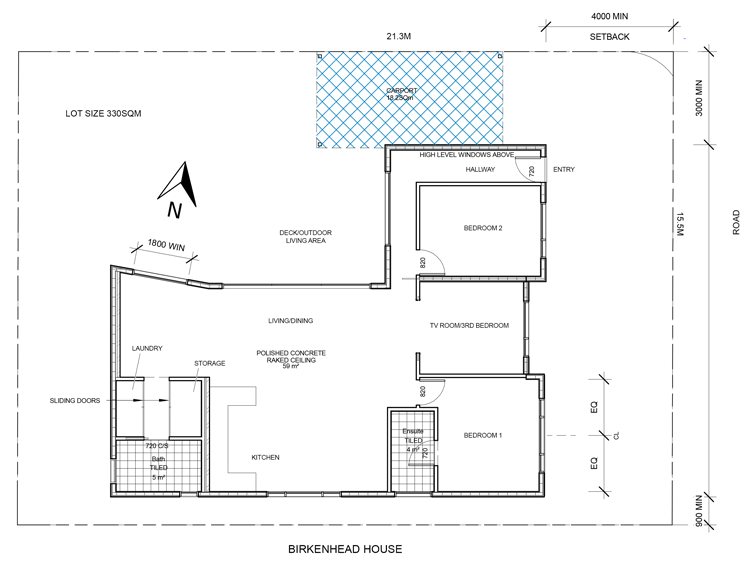

Size: 125m2

Size of land: 330m2

Cost: $150,000

Clad in Zincalume steel, the environmentally responsive, modern design of this portside dwelling ties itself to the area through the use of building materials used in the area historically.

After six years of living in a poorly insulated early 1900s stone villa in Adelaide, where winter temperatures inside the building were colder than outside, the owners were ready to build a more climate-responsive dwelling.

Although at 125m2 the two-bedroom home is small by Australian standards, it is more than sufficient for the occupants. The design embraces the owner’s love of entertaining, and features a good-sized open plan kitchen/living area leading onto a large deck, a much-used indoor/outdoor living space. The hallway wall doubles as a display area.

Site, block orientation, location and climate

The two-bedroom dwelling is in Birkenhead on Adelaide’s northern beaches. Adelaide has very hot, dry summers with heatwaves often exceeding 40°C, and cool to cold winters requiring heating. A well-sealed building fabric, insulation and thermal mass are priorities in this climate, to keep heat in during winter and out during summer. It’s also important to remember that it’s practical to design for the normal conditions rather than the few really hot weeks.

Design brief

The main objectives of the project was to build a passive-designed house that heats and cools itself on a reasonable budget, situated on a modest-sized block in the Adelaide suburbs. The owners were often told that an ‘eco house’ is expensive, and were determined to prove it did not have to be. They felt strongly that anyone could achieve good passive design outcomes by thinking about orientation, material selection, local climate and designing to the site location before starting a build.

Design response

While designed for two people, the building layout is flexible and can be zoned. Clever location of doors is used to aid zoning so the most used areas of the home receive optimal heating and cooling benefits.

As with all builds, some challenges presented themselves. The local council required two off-street parking spaces with at least one under cover. The house was sited at the southern end of the block and the car spaces to the north-east, allowing for future extensions and to maximise solar and winter heat gain. A window was inserted on the northern wall above the carport roof to ensure maximum winter sun.

The designer worked hard to maximise the limited space. At 4.2m x 8m, the large, north-facing deck makes the home ideal for entertaining. The size of the home is suitable for a couple, either just starting out or downsizing later in life. The third room is currently being used as a TV room but could be used as a study or guest bedroom.

The owner regrets that he wasn’t able to install thermally broken windows. 'The window supplier wasn’t helpful at all. Even double-glazing was an issue, as the glass had to come from Melbourne. Overall, asking for high-performing windows was difficult—some suppliers wouldn’t even give me a quote on it.' This issue may be resolved in the future as the market becomes more interested in high-performing windows.

The concrete slab floor acts as thermal mass to absorb the warmth from the northern sun during the day.

Photo: Mark Clayton, Sustainability House

Monitoring performance

Several monitoring systems in the building and are tracking internal temperature, humidity, energy consumption and solar energy production.

A weather station on the roof monitors external temperature, humidity, wind direction, speed and rainfall. Additional data loggers (Hobo MX1011) are located in the kitchen/living area and bedrooms to track internal temperature and humidity (readings are taken hourly). These simple devices connect to a smartphone via Bluetooth, making downloading data very easy. Data is then plotted in spreadsheet or graph format, allowing easy comparison with the temperature graphs generated by the NatHERS software.

Thermal mass

Internal thermal mass keeps a house warmer in winter and cooler in summer. In this home, a strong emphasis has been placed on passive solar design and thermal mass.

Internal thermal mass in the form of two recycled brick walls in the kitchen/living area was created on the western wall.

Reverse brick veneer

The reverse brick veneer helps the home minimise heat gain in summer. The section (from inside out) is 90mm brick / 30mm air gap / 11mm OSB / 93mm EPS / 11mm OSB / breathable membrane / 15mm air gap / Zincalume. By using recycled red bricks with a very subtle American bond pattern worked into it, and cut-and-struck lime mortar, the walls not only add thermal performance but look great.

The reverse brick veneer walls provide an extra layer to the building fabric on the western façade reducing heat build-up during the long summers. Many more temperate areas may only require the SIP to achieve a comfortable home, an issue worth discussing with an experienced accredited NatHERS assessor.

Insulation

The R3.2 insulation in all walls and R6 bulk insulation in the ceilings boosts the home’s thermal performance.

Windows

North-facing windows in the kitchen/living area allow passive solar gain in winter while clear-eave calculations keep the sun out in summer. There is no western glazing to the thermally conditioned zones. Bedrooms are in the cooler part of the house, with windows located to the east allowing the occupants to wake up to the sun each day.

The windows are double glazed aluminium 6/12Arg/6 with the sliding door glass at 6.38mm for easy handling (double glazing can be heavy). This size also helps maintain a higher solar heat gain coefficient, and is a factor in determining whether you are trying to maximise winter warmth or exclude sun from a design.

Window location was calculated on the site’s prevailing wind patterns in summer to assist with cooling. Breeze paths have been created and window heights allow for stack cooling.

The SUHOstudio YouTube channel has a video showing the winter solstice solar gain through the north-facing lounge room doors and windows of the house.

Window design and location makes the most of prevailing breezes and good orientation.

Photo: Mark Clayton, Sustainability House

Floor treatments

Sisal carpet covers the floor in the two bedrooms with exposed concrete floors throughout the rest of the house. These were sealed with a no volatile organic compound (VOC) oil. No VOC, natural paints, primer, undercoats and sealers were used on the ceilings, walls and woodwork to eliminate toxins and maximise air quality.

Wall construction

The owners were keen to ensure their new home was built well, reasoning that a well-designed building is irrelevant if it’s not built properly.

The speed and ease of construction impressed both owners. The structural insulated panels (SIPs) come with a pre-chased hole running horizontally at 300mm, 450mm and 1200mm to run electrical cables. The couple put the panels together themselves, running a chasing string through the holes. This meant that when the electrician arrived on site to install the cabling, all that needed to be done was to tie a wire to the string and pull.

Airtightness

Thermography analysis on the final building fabric and an air-pressure test showed the house achieved 3.6 air changes per hour (ACH) at 50 pascals. Given that the average project home in Australia rates at around 19 ACH, this puts the Birkenhead home in the category of best-sealed houses in the country. However, designers need to be aware that if a house is too well sealed it may require a mechanically forced air system, as in European-style Passive Haus designs.

Heating and cooling

Ceiling fans have been installed in the bedrooms and living area. There is no other mechanical heating or cooling for the house.

Floor plan of Birkenhead house design.

Plans: SUHOstudio

Solar photovoltaic (PV) system

With a 3.5kW grid-connected solar photovoltaic array on the roof, the family produces more energy than it uses, making this an energy-positive dwelling.

Heat water

A 325L heat pump provides hot water. Choosing not to run gas to the dwelling allows for the possibility of running the whole house on solar storage batteries in the future.

Lighting

Lighting was carefully considered at the design stage. There are no downlights as these can compromise the effectiveness of ceiling insulation, and in general, the fewer holes in a building’s envelope, the better it will perform. By building the house to maximise good natural light, the need for artificial lighting was kept to a minimum.

Water saving

The homeowners installed two rainwater tanks around the property with a total capacity of 7,000L. The tanks are plumbed together and service the whole of the house and garden. The water supplies for house, garden or both can be manually changed from the tanks to the mains if required. There are also low-flow taps and showerheads along with 4.5 star WELS (Water Efficiency Labelling and Standards) toilets.

Questions and answers

Your Home (YH) asked designer and owner Mark Clayton (Mark) about some of the choices he made on the build:

YH: Why did you choose SIPs (structural insulated panels)? Were they easy to source, and did you have any concerns about the foam insulation used in them?

Mark: We chose SIPs as they delivered many benefits:

- They are an air-tight building fabric with a quick build time. As SIPs are pre-fabricated it really is just a job of fitting them together. Completing the full structure took just two weeks work.

- SIPS are structural, so I didn't have to worry about the engineering specs. It’s all been pre-calculated, including things like the lintels over openings. This also meant I didn't have to learn the timber framing code on how to build structural stud walls—a timesaver.

- Because SIPS don’t have thermal bridging, the solid state insulation will not fall into cavities or compress on its own weight over time. I knew we were getting something that would last.

- Price-wise, the product was about the same but the thermal performance was much better.

There are several SIP suppliers entering the market, I chose this one as many of the SIPs use metal frames and I prefer to work with timber.

The no VOC oil was supplied by Livos and the slab was burnished. This was done for several reasons:

- We were after a warehouse feel to the build and I liked the finish the copter leaves on a slab. The concrete team was aware of this and they spent several more hours than normal coptering the slab to make it smoother (seven hours in total, I understand two is normal). A 32MPa (megapascal) mix was used which is harder than concrete used under carpets (this is normal for exposed slabs).

- By not grinding the slab we made significant cost savings. Slab grinding or polishing costs about $80–$110 per square metre.

- By leaving the slab as it was and sealing it with oil, there was no need for tiles and a tiler, again reducing costs.

YH: Did you do anything special or different in the build, like extra sealing tape at the top and bottom of the SIP? Some have suggested that you need forced air once you are below 6 air changes per hour. Did you consider this or is opening windows all you need to do? What about fresh air in winter?

Mark: Most of the benefit was because we used SIP's. I also made sure that when we installed the windows they was installed well and silicon was used to seal up gaps.

- By not having downlights we minimised ceiling penetrations.

- The SIPs are pre-chased for the electric ring main and therefore not opening into the cavity as per usual in brick veneer construction. All switches have been located on internal walls (which are insulated) therefore reducing holes in plasterboard that connect to outside or ceiling space.

It has been suggested that forced air is required, we leave both bathroom windows open all year round, in winter this helps minimise moisture in the building. As the building heats up the slab and internal thermal mass inside, we find that opening a window or the sliding doors for 10 minutes each day provides effective air change. As the heat is stored in the thermal mass, the fresh air is quickly heated and the internal comfort is not affected. I would agree if no windows were ever opened then indoor air quality could be an issue; again, it's about understanding how to ‘drive’ the house and using common sense.

Evaluation

The owners’ focus now is to educate others in what they have done, and how and why they have done it. They are very happy with their home and want to encourage others to learn from their approach and build in keeping with the home’s local climate, while showing that outstanding results can be achieved on a small budget.

Their main advice for anyone keen to undertake this kind of build would be to plan well, understand the work flow and be prepared. They advise keeping contractors in the loop about where you are heading; the last thing you want is to get too far ahead and make their job harder.

The owners also found that recommendations were invaluable. If a good contractor recommends someone, chances are they will share the same quality of work. The owners stated that they were very lucky with the contractors they used and have recommended them to others looking to build.

Author

Mark Clayton, Sustainability House

Learn more

- Next case study - Glanville, Adelaide, SA

- Read Materials for ideas on materials for new home construction

- Explore Design for climate to find out how your home can best suit your location